SXYS TOOLS providing the DownHole(DH) Motors with the smaller OD including OD2 1/8", 2 3/8", 2 7/8", well used for directional drilling in coal and hard rock mining drilling.

The Down Hole Motor is driven via fluid pumped into the motor, which then turns it into a mechanical rotary motion through the form of a rotor. This rotary motion is applied to the Drill Bit (PDC bit, impregnated diamond bit) and the drill bit rotates, it cuts through the rock formations, creating borehole. The drilling fluid carries the cuttings back to the surface, where they are separated from the fluid and discarded.

The direction of the motor can be determined by a "bent sub ". These subs can be fitted to the DHM to adjust the “angle” of the motor and how fast it can turn within the hole.

Fixed bend housing available, what degree we can provide? Normally 1degree, 1.25degree, 1.5degree or acc. to customers’ requirements.

Adjustable bend housing available, 0-3degree range for your adjusting on site easily.

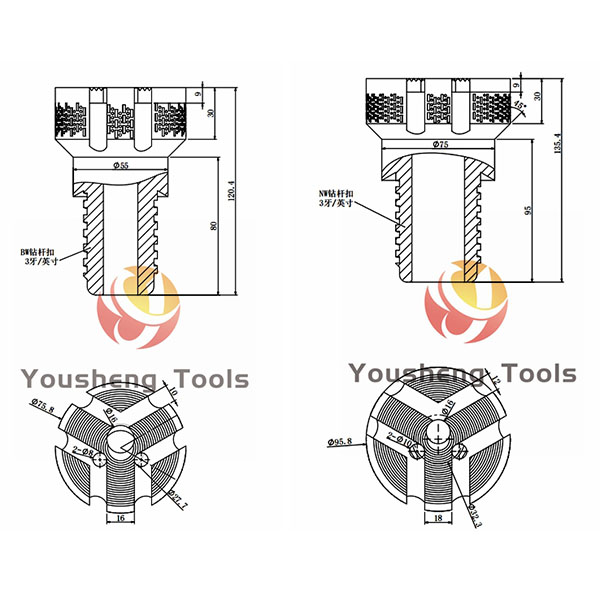

Connection Type: API REG Thread, BW Thread, NW Thread, etc.

Different lobes and stages to meet your requirements of ROP, TORQUE, FLOW RATE.

Standard Rubber, hard Rubber(or call high performance rubber) for your choosing.

#Downholemudmotor #drillingmotor #BHA #drilling #HDD #oildriling #pilotdrilling #drillandblast #drillbit #PDCbit #PDCreamer #rockreamer #rockcrossing #hardformation #highspeedmudmotor #hightempeturemudmotor #directionaldrilling #diamonddrilling #exploration #miningnews #minerals #miningperu #bigtorquemudmotor #coalmine #waterwelldrilling #drilling #DHM #CTmotor #HorizontalDirectionalDrilling #DirectionalDrilling

Post time: Jul-18-2023